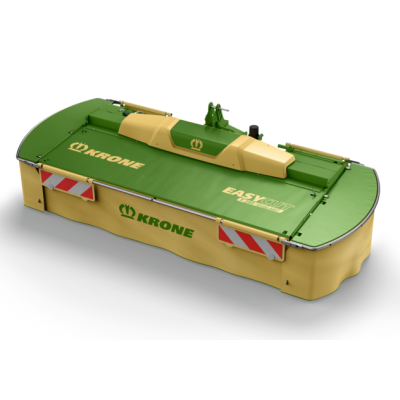

EasyCut F Highland framsláttuvélar

kr. 2.299.000 – kr. 2.699.000

EasyCut F Highland framsláttuvélar

kr. 2.299.000 – kr. 2.699.000

EasyCut B fiðrildi - sláttuvélatvenna

kr. 4.899.000 – kr. 9.999.000

EasyCut B fiðrildi - sláttuvélatvenna

kr. 4.899.000 – kr. 9.999.000

EasyCut R miðjuhengdar sláttuvélar

kr. 2.099.000 – kr. 3.699.000

Það sem einkennir EasyCut sláttuvélarnar eru þægindi fyrir notandann, nákvæmur skurður, áreiðanleiki og ending. Vélarnar eru hannaðar fyrir mikla notkun og eru þekktar fyrir lipurð. Drifið er á sláttuborðinu sjálfu svo öll vélin getur leikið á miðjuhenginu. Þannig elta EasyCut vélarnar túnin vel. Fáar vélar komast nálægt Krone hvað varðar endingu og lítið slit. Sláttuborðið er lokað, þarfnast lítils viðhalds og er ótrúlega hljóðlátt.

Verð eru birt án vsk. Verðlistinn miðar við gengi EUR = 145 ISK. Tilboðsverðin gilda af forpöntuðum vélum til 5. janúar 2024. Forpantaðar vélar eru afhentar samsettar heim á hlað.

Lýsing

EasyCut R

- Quick-change blades

- SafeCut: Individually protected discs

- SmartCut: Stripeless cuts from optimum blade overlaps

- DuoGrip: The centre-of-gravity suspension system with dual grip control

- Optimum ground pressure control by means of responsive and adjustable springs

- Compact in transport as the mower tilts to the middle of the tractor – for optimum weight distribution and visibility

The cutterbar

- Fully welded: Robust, sealed and permanently lubricated

- The durable satellite drives have massive spur gears for quiet running and superior efficiency

- No inner shoe for trouble-free cutting

The enclosed and fully welded cutterbar meets the highest quality standards and operates dependably and leak-free over many years of hard work. Massive and oil-immersed spur gears impress by very quiet and reliable running in sustained peak-load operation.

Using welding robots and CNC technology, KRONE manufactures its cutterbars to the highest quality standards, ensuring they are fully welded and permanently lubricated. After all, the cutterbar is the heart of every disc mower.

The KRONE developed satellite driveline comprises massive spur gears with up to 66 teeth which transfer the power all the way down to the very last disc. The large-diameter gears rotate at reduced speeds, with a higher number of teeth meshing with the neighbouring gearwheels for even quieter running, ultimate efficiency and maximum longevity. The auxiliary gears drive one disc each and as a result are exposed to only minimum loading.

SmartCut

- The wedge-shaped cutterbar guarantees clean cuts

- Heavy-duty spur gears run in widely-spaced double bearings

- Swathing or spreading depending on needs

The wedge-shaped cutterbar offers great flexibility to adjust through a large range of settings and leave a short stubble in meadows and pastures as well as long stubble in long-stemmed field crops. An EasyCut mower delivers a reliable performance and clean cut.

With some discs turning in pairs towards each other and others turning away from each other, it was necessary to redesign the degree of blade overlap to ensure cleanest cuts. For stripeless cuts in light and young crops, we have therefore increased blade overlaps on the discs turning outwards (SmartCut). In addition, the blades turning to the rear are set further apart to encourage a smooth flow of large volumes of crop.

With discs spinning in the B sense of rotation, EasyCut spreads the material across the full cutting width. All discs turn in pairs, spreading the material across the working width for faster and more uniform wilting.

Safe road travel

- The unit folds into an over-centre position, reducing the transport height and optimising the weight distribution and view to the rear

- The unit is lifted hydraulically and without raising the tractor links to make the headland turn

- Large suspension travel

Implementing a large work width on a mower poses a special challenge to the designers who have to reconcile demands for high work rates with those for good transport and contouring qualities. The solutions are reflected by the KRONE Z-form, the low pivot point, the over-centre transport position and the headland position that does not require operating the tractor’s link arms. KRONE disc mowers offer safe travel and best cuts even in difficult conditions.

The unit folds hydraulically beyond TDC, the single-acting ram on the EasyCut R 280 and R 320 has an accumulator and folds 110° over top dead centre, the double-acting ram on EasyCut R 280 CV, R 320 CV and R 360 folds 124° for better road stability and visibility. Actively folding and unfolding, both versions make for trouble-free changeovers.

Z-shaped arms enable large vertical travel (29° up, 20° down) – ideal for mowing banks and verges.

The Z-shaped arm has a low pivot point for a reduced transport height and yet offers a large ground clearance for smooth travel on rutted field roads.

Shifting the machine weight to the middle distributes its weight more evenly on to the lower links, which improves the tractor ride and gives operators a clear view behind in the mirrors.

SafeCut

- Full driveline protection for added reliability

- Neighbouring discs will not collide

- Wear-free

- Quick-change roll pins for minimum downtime and costs

Colliding discs may cause damage and involve costly repairs. KRONE SafeCut offers a maximum of protection and peace of mind. The award winning system on all EasyCut models offers a unique level of protection and operator comfort. SafeCut is a base specification feature on all EasyCut F models.

There is no load on the roll pins during operation. The bearing is tensioned by a nut and two clamping screws. As a result, the roll pins do not suffer from material fatigue and even after many hours of operation they will break only at their inbuilt load level.

Each disc on the mower has its own individual impact protection. When the blade hits an obstacle the shockload is transferred to a roll pin which breaks. As a result, the disc automatically threads 15 mm up on the drive shaft.

If the system is suddenly overloaded, the impact is not directed to the spur gears in the driveline, instead a roll pin in the sprocket drive shaft shears off. The pinion shaft continues spinning, jacking up the disc in question, moving it out of the risk zone and the orbit of the neighbouring discs. As a result, SafeCut prevents damage to the spur gears and the neighbouring discs. The roll pins can be replaced in just a few minutes and cost next to nothing.

DuoGrip

- The DuoGrip system – centre-of-gravity suspension and linkage control

- Uniform ground pressure across the entire work width

- Excellent guidance: less side thrust, clean cuts

- Short and high-strength beam

A clean cut is fundamental for clean forage. Clean cuts are attributed to the special design of the cutterbar and the special suspension. The special KRONE DuoGrip suspension system suspends the disc mower in its centre of gravity and provides lateral guidance at the same time. Maintaining a consistent ground pressure across the full work width, the design leads to cleanest cuts on the one hand and light pulling and optimum lateral control on the other.

The parallelogram linkage absorbs lateral forces and guides the unit in direction of travel. At the same time, it helps reduce the load on the jib and the suspension system in the machine’s centre of gravity. The two rods also indicate to the operator whether the tractor linkage is at good height.

La faucheuse est fixée à l’extrémité du bras par le biais d’un axe logé dans la sphère. Avec pour résultat une importante plage oscillante et un suivi exemplaire des reliefs du terrain. Une sécurité anticollision est également intégrée de série.

Suspended in its centre of gravity rather than centrally: Maintaining a uniform pressure across the entire work width is a requirement that is thoroughly met by Krone disc mowers, courtesy of a gearbox that is arranged on the inside of the machine where it shifts the centre of gravity to the side. This, the short jib and two extra braces give maximum stability while keeping the weight down – and delivering best results in rough going.

High work rates and clean cuts

- Suspension springs with central control ensure uniform cuts and an optimum ground pressure

- Ground pressure control without tools

- Hydraulic ground pressure control is an option

- Two-fold impact damage protection

The hydraulic and the mechanical suspension springs are extremely responsive and provide perfect cuts even in undulating terrain and at high forward speeds. This is the first step in making clean and high-quality forage and a requirement for a fast and uniform re-growth. The kinematics between the coil spring and the main beam maintain a nearly consistent ground pressure, even in undulating terrain.

Adjusting the spring manually is a fast and easy job. Simply refit a pin to select the target tension. The ground pressure drops as the spring tension increases.

The spring can also be adjusted hydraulically as an option for instant ground pressure changes on the move. The spring tension is released from the seat before the machine is removed from the tractor.

The standard impact damage protection system on EasyCut R models gives you peace of mind as you work along borders, fences and hedges and suddenly collide with an obstacle. When the system trips, the mower swings 1.20 m to the rear and up to 40 cm upwards and clear out of any obstacle. After the obstacle has been passed, the mower swings automatically back into work position.

EasyCut R 280 | R 320

- Manual or hydraulic ground pressure control

- Low-maintenance, frictional drive; no belts

- KRONE SafeCut cutterbar protection is a standard feature

- Cantilevered guard frame ensures smooth crop flow

Looking for a high-capacity mower that works at widths of about 3.00 m? Then the KRONE EasyCut R 280 and R 320 with DuoGrip disc mowers are for you. These machines are packed with innovative features such as the DuoGrip centre-of-gravity suspension with manual or hydraulic suspension control, the unique auto-reset system and the optimized cutterbar for stripeless cuts.

The spring on EasyCut R 280 and R 320 is adjusted manually or hydraulically as an option. for best contouring in all types of terrain and also at high forward speeds.

EasyCut R280 and EasyCut R 320 have adjustable lower link pins that allow the machine to run offset behind the tractor and cut at full width at any track width, on side slopes and in combination with a front mower.

When the mower moves into transport position, the guard folds back to reduce the transport height. When the machines lowers into work position the guard, too, moves back into work position.

Only one single-acting ram with accumulator is required to swing the rear-mounted EasyCut R 280 and R 320 mowers from work position to headland or transport position and vice versa.

The vertical storage position saves space in the machine shed. The optional stands give the machine good footing and are useful for attachment and removal. But of course EasyCut R 280 and EasyCut R 320 also store in horizontal position.

EasyCut R 360 | R 400

- 3.60 m or 4.04 m working width

- Forming two swaths or spreading the material

- Hydraulic cutterbar suspension is available as an option

- Excellent value for money

The high-capacity EasyCut R 360 and R 400 mowers are mounted machines that score on enormous work rates and productivity, performing equally well in forage harvesting and field extensification.

These two models have particularly strong headstocks. They can move sideways and the lower link pins can be refitted to adjust to suit different tractor track widths and to team up with a front mower.

Spreading across the full width: Spreading the material leads to faster wilting because it exposes a larger surface to the sun and wind, leading to very high-quality forage and fewer losses.

Spreading across the full width (B sense of rotation): The discs on the EasyCut R 360 and R 400 models work in pairs, with two discs running with opposed action spreading the material across the full width. Forming two swaths (A sense of rotation): This is an option for those who try to avoid running over the cut crops. These models have only the central discs run with opposed action, producing two swaths.

EasyCut R 360 in road transport: The EasyCut R 360 model swings up and beyond TDC behind and very close to the tractor improving ride comfort especially on small tractors.

The EasyCut R 400 moves hydraulically into the transport position behind the tractor and folds up the front curtain. This turns the machine into a narrow, low-profile transport unit for smooth passage underneath bridges and through gates and for safe travel on public roads.

Frekari upplýsingar

| Vinnubreidd | 2.73 m., 6 diskar, 2.73 m., 6 diskar með knosara, 3.17 m., 7 diskar, 3.17 m., 7 diskar með knosara, 3.6 m., 8 diskar, 4.04 m., 8 diskar |

|---|