Vendro lyftutengdar snúningsvélar

kr. 1.399.000 – kr. 4.399.000

Vendro lyftutengdar snúningsvélar

kr. 1.399.000 – kr. 4.399.000

Vendro T dragtengdar snúningsvélar á vagni

kr. 3.149.000 – kr. 9.999.000

Vendro T dragtengdar snúningsvélar á vagni

kr. 3.149.000 – kr. 9.999.000

Vendro Highland lyftutengdar snúningsvélar

kr. 1.399.000 – kr. 2.849.000

Highland línan frá Krone er ný lína af framsláttuvélum, snúningsvélum og rakstrarvélum sem hönnuð er fyrir erfiðari aðstæður. Það sem gerir Highland frábrugðið öðrum tækjum er að þau leggjast nær dráttarvélinni og þyngdarpunkturinn er mjög neðarlega. Þannig hefurðu mikið betri stjórn á tækjunum í brekkum og erfiðu landslagi.

Verð eru birt án vsk. Verðlistinn miðar við gengi EUR = 145 ISK. Tilboðsverðin gilda af forpöntuðum vélum til 5. janúar 2024. Forpantaðar vélar eru afhentar samsettar heim á hlað.

Lýsing

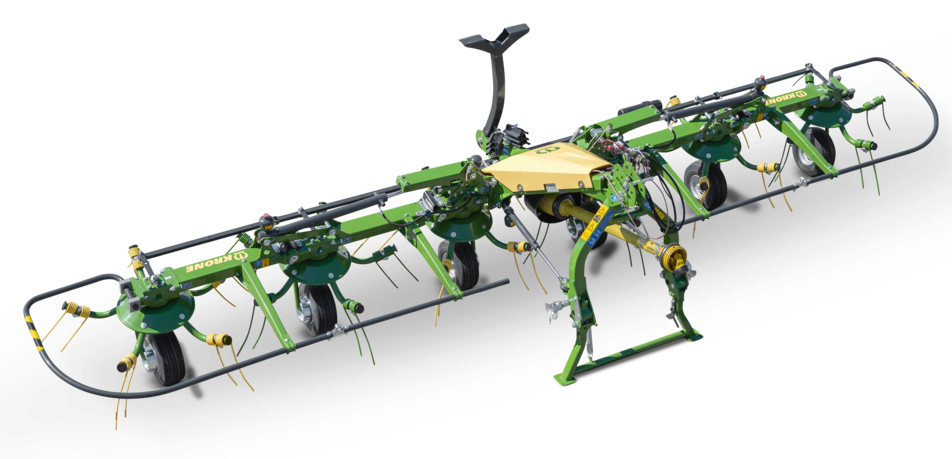

Vendro Highland

Getting the timing right with the proper rotor

The new KRONE OptiTurn rotor with 3D tines is the key for clean and efficiently conditioned forage. Featuring a curved and patented design and working close to the rotor gauge wheel, these tines pick up the material cleanly and uniformly across the full work width. The intensity of conditioning is changed according to conditions and crops without the use of tools and by just setting the spreading angle to one of four positions. This makes the KRONE Vendro an effective dual-purpose machine.

Producing a uniform and fluffy matt, this KRONE rotary tedder cuts down the number of hours the crop spends drying, giving you enough time to clear the field before the rain.

Changeovers to border spreading are made by adjusting the gauge wheels under the rotors. This is done hydraulically from the convenience of the cab. The border spreading feature can also be used for uphill tedding. Stable tracking without drifting is achieved by hydraulic damper braces in combination with gauge wheels being fixed by the border spreading linkage. This is the secret behind uniform and accurate spreads, even on the steepest of slopes.

The KRONE OptiTurn rotors

- The rotor wheels run extremely close to the rotor providing optimum contouring

- Curved 3D tines lift and spread the crop perfectly

- Rotors overlap for clean and uniform spreads

- Optimum spreads for uniform wilting and highest-quality forage

The KRONE OptiTurn rotor design make real big-time. The special design sees the rotors overlap generously so the KRONE OptiTurn tines can lift the crop cleanly and spread it uniformly at an optimum width for fast wilts and optimum animal feed. This technology boosts your productivity not only in the field but also in the milking parlour.

For consistent spreads in any type of condition, the tine arms of two adjacent rotors overlap generously. A consistent mat of crop speeds up the process of wilting, allowing you to produce high-quality forage in narrow harvest windows.

An optimum quality of work is delivered by the new 3D tines. The curved shafts lift and throw the material with greater ease which is the first step in making clean and high-quality forage.

The two shafts in one pair of tines are unequally long so their tips are always in parallel as they hover above the ground, lifting the material cleanly and without contamination. This so-called combing effect mixes the various layers of the mat for uniform and con-sistent wilts.

The OctoLink finger clutches

- KRONE OctoLink finger clutch – eight fingers make frictional Connections

- The driveline to the rotors is never cut

- No risk of driveline damage due to operator error

- Maintenance-free driveline minimises service and maintenance and maximises lifetime

All Vendro tedders benefit from the tried-and-tested KRONE OctoLink finger clutches. The rugged units require no lubrication at all. This is the kind of dependable and low-maintenance machine you have always wanted.

Each rotor is driven by a well-proven finger clutch which consists of eight fingers that make a frictional and reliable connection inside the driveline. No matter which angle, the power flow to the next rotor is never cut off. The extremely robust finger clutches are absolutely lubrication-free, freeing you from time-consuming servicing and making you more productive.

The eight-finger clutches make Vendro an enormous agile machine. They allow the outboard rotors to fold 180° towards the middle without any risk of damaging the driveline. Thanks to this enormous flexibility you can store the machine in tight space and travel at a reduced transport height.

Attachment and storage

In storage position the tedder rests on two wide stands rather than on its own wheels. In this position, it is also easily attached and removed from the tractor.

The prop stand at the rear counterbal-ances the stroke of the damper struts as the machine is removed from the tractor. The stands raise the wheels from the ground avoiding tyre damage from long periods of storage.

Adjusting the angle of throw

- Altering the angle of throw alters the intensity of conditioning

- A steep angle controls tedding, a shallow angle controls turning

- Easy adjustment to 13°-19° angles without tools

Tedding or turning? Vendro allows you to change from tedding to turning or vice versa at the spur of the moment. Simply change the spreading angle and the crop is conditioned at the required intensity.

All tedders have this pin-and-hole system as a standard feature which allows you to alter the spreading angle within a range of 13° to 19°. The spring-loaded pin adjusts the angle quickly and easily in four steps. No tools required, no pins need cottering.

The angle of spread controls the intensity of conditioning. A steep angle results in intensive tedding and a shallow angle in gentle turning. This way you are able to operate the machine to your specific needs.

Error: Product SKU not found.Error: Product SKU not found.Error: Product SKU not found.Error: Product SKU not found.Error: Product SKU not found.

Frekari upplýsingar

| Vinnubreidd | Vendro 420 Highland – 4×5, Vendro 620 Highland – 6×5, Vendro 820 Highland – 8×5 |

|---|

| BRAND NAME | |

|---|---|

| GROUP | |

| GROUP DESCRIPTIONS |